Stock control is key a key part of managing a restaurant. Why? Because your business’s profits or losses are partially determined by the amount of food inventory you buy and what price it’s sold at.

Food inventory management helps keep costs of goods sold and losses associated with food waste to a minimum while assuring that each customer gets fresh, quality produce.

If you’re looking to maximise your stock’s return on investment, you’re in the right place. In this post, we’ll cover seven tips for improving your restaurant’s stock management.

- Calculate your cost of goods sold

- Track Ingredient Loss

- Use Stock Control Software

- Use Ingredient Reports

- Be Consistent

- Follow FIFO

- Minimise Food Waste

Let’s dive in!

1. Calculate your cost of goods sold

With good stock management, it’s easier to get a precise picture of your restaurant’s profits and losses.

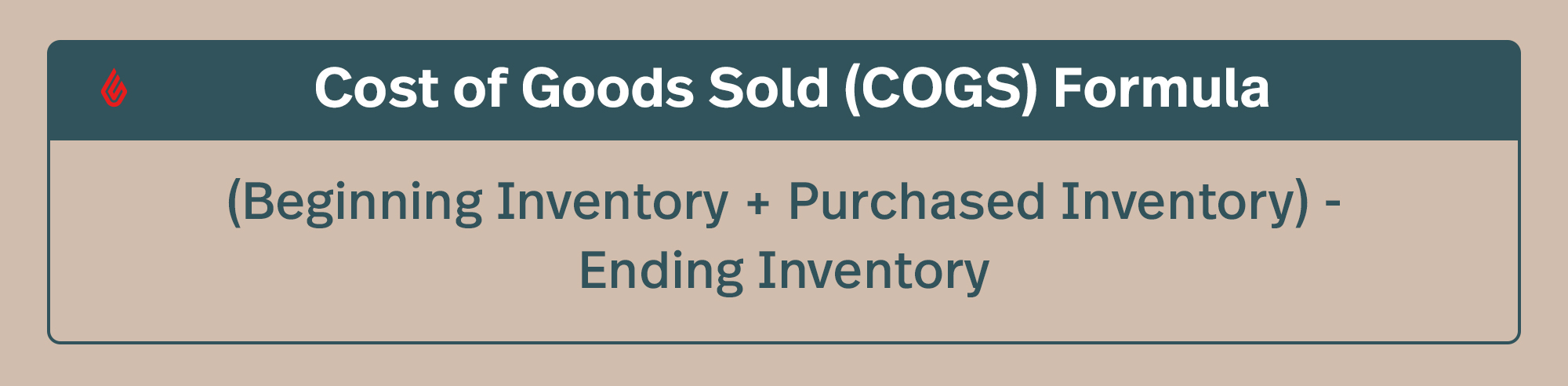

To figure out how much your food inventory is costing you over a specific period of time, it’s necessary to work out your Cost of Goods Sold (COGS).

The equation itself is pretty simple. Say you want to know the COGS for a period of four months—from August to December. To work this out you need three values:

Beginning inventory: The total amount of stock you have at the beginning of August.

Purchased inventory: All stock purchased between August and December.

Ending inventory: The total amount of stock you have at the end of December.

Price your menu and turn a profit with our Food Cost Calculator

Calculate your restaurant's food costs within seconds. Click below to download

So let’s say that your food inventory at the beginning of August was worth £2000. During that period of four months, you spent a total of £7000 on stock. By the end of December, your stock was worth £4000.

To get the COGS, add your beginning inventory to your purchased inventory, then subtract your ending inventory from that total.

COGS = £9000 – £4000

COGS = £5000

Once you’ve worked out your COGS, whatever you have left after that is your gross profit, which then goes on to determine your net profit margin

For that reason, the lower your COGS, the higher your gross profit. A restaurant should aim to reduce its COGS as much as possible while maintaining its sales volume and food quality.

Optimising your COGS depends on good food inventory management. Having a good knowledge of what’s going in and out of your business is imperative for making a profit and avoiding losses.

2. Track ingredient loss each service

Stock doesn’t always do what you want it to, that’s why constant attention to detail is important.

Say you run a Meze restaurant and you buy four 1kg tubs of Hummus for £48. Two weeks later your entire stock is gone. You sell hummus in units of 50g at £3.50 a unit so altogether the purchase should have made you a total of £280. Subtract the total cost of the purchase, and that’s £232 in gross profit. Nice!

That’s not, however, what the books are showing. So where did all that hummus go?

It’s hard to say. A delivery driver could have dropped some in transit, a staff member could have sent the wrong items, or simply taken some home for themselves. Each of these scenarios is equally plausible and are typical cases of spillage, error and theft.

In an ideal world, all your restaurant’s stock would end up on customer plates and you’d be able to associate every ounce and millilitre of inventory to transactions.

Unfortunately, we don’t live in that world, and you should always consider where your stock could end up other than where you want it to.

Keeping track of every spill and mistake may be a little extra work, but for bookkeeping purposes, it’s important to get your staff into the habit of doing so, whether it’s a spillage or a miscommunicated order.

Without a certain degree of diligence, you won’t have an accurate picture of where your inventory is going. If you don’t know how much you’ve lost, you don’t know how much you’ve earned.

3. Use stock control software

When it comes to effective stock management, memory and attention to detail aren’t enough. Mistakes happen and people forget things. Luckily technology can facilitate accurate stock control and minimise avoidable errors.

A good restaurant ePOS system will often have built-in food inventory management features that help restaurateurs accurately order, count, manage and sell their stock.

As a restauranteur, stock most commonly refers to materials used in dishes and drinks, down to the last napkin. One ingredient may be used in multiple dishes on your menu. Having a system that monitors what ingredient goes in which dishes (and how many of those dishes you sell) helps you accurately gauge how much food inventory you need to buy to fulfil demand without wasting leftover ingredients.

From your restaurant ePOS software, you can also select the quantity you’d like a unit for a specific ingredient to be, as well as the menu price and cost of goods sold for that unit. When you assign ingredients to menu items, the smallest quantity you can assign is one unit.

You should therefore select a unit that represents the smallest quantity for the ingredient. For example, if you stock ground beef in units of ¼ pound, a quarter pounder burger will use one unit of ground beef and half-pound burger will use two.

You can assign these units of ingredients to menu items, noting the cost and quantity of ingredients that go into that item.

To do this in Lightspeed Restaurant, go to Back Office > Products > Ingredients > Add Ingredients

Here, you can name the ingredients and give them a specific SKU number which will allow your ePOS system to keep track of your inventory levels the quantity of a particular dish or drink you’ve sold. This is stored in the reports feature.

Accurate knowledge of cost per unit lets you markup your menu items from a more informed place. It’s common practice for restaurants to mark-up their menu items by 300% of COGS in order to stay profitable.

If you’re buying ground beef at at 74p per unit (¼ lb), you’d do the following equation when calculating the menu price for a quarter pounder burger:

COGS + 300% = Menu Price

€1.48 + £4.44

Menu Price: £5.92

Remember that this is just the price for the burger itself, you also have to include the bun, lettuce, tomatoes, toppings, fries, the gas or electricity that goes into grilling it, the fee of the platform that helps deliver it and the rent for the building it’s cooked in.

All of these factors determine the final menu price of the dishes your ingredients go into. By tracking exactly how much of any ingredient goes into what, marking up becomes easier.

This is just another example of how good stock control leads to increased profitablity.

With accurate data saved into your ePOS, you can compare the forecasted revenue, actual revenue and amount of stock purchased. This makes managing a restaurant easier, allowing operators to monitor how much revenue was lost due to wasted stock.

See Lightspeed in action

Watch our webinar, and discover how Lightspeed can drive your business forward.

4. Use Ingredients Reports

So, you’ve entered each ingredient you have in stock into your ePOS and assigned each ingredient to a menu item in their respective quantities. The next thing is to get a consolidated view of where your stock is going.

An Ingredients Report displays the quantity and total cost of ingredients sold in a specific period. It’s a useful tool in determining stock levels for sold products within a specified date range.

This data doesn’t only help you with inventory management. Ingredient Reports give you the ability to track sales for particular stock items over time, helping you make informed decisions concerning purchasing, promotions and pricing strategy.

For example, you may notice that you haven’t been selling a particular ingredient as much as you used to. Have you changed supplier? Perhaps the quality isn’t as good anymore.

To boost sales for this product and avoid a loss in profits, you can put a promotion on a dish that uses that particular ingredient and sell it before it spoils.

With accurate sales data, it’s much easier to make these kinds of calls.

5. Be consistent

Without a consistent practice of food inventory management, you’re prone to error and inefficiency. Inconsistent stock control will eventually chip away at your bottom line.

First, determine how frequent your stocktakes should be. Frequent checks—say prior to opening and after closing each day—mean you can pick up on losses sooner than doing it on a quarterly, monthly or yearly basis.

If you’re not carrying it out yourself, make sure you’ve elected a reliable member of staff to be responsible for your stock, such as your chef or maitre d’.

The key to accurately managing inventory (and spending less aggregated time doing so) is to perform stocktakes consistently. By doing it at the same time, and electing one staff member to be responsible, you avoid revenue-draining mistakes like inventory shortages and spoilage.

6. Follow the FIFO inventory costing method

FIFO is an inventory costing method where you assign the cost of your oldest stock to the beginning inventory in your Cost of Goods Sold calculation. The cost of your newest stock is assigned to the ending inventory.

FIFO is particularly suited to restaurants because it reflects how physical stock is most commonly rotated: oldest first, newest last.

This not only ensures the freshness of ingredients going into your menu items, but allows you get a more accurate idea of what your inventory is costing you over time.

As well as that, with the food prices rising all the time, a FIFO assessment of stock levels ensure that you use the older cheaper stock before your newer and likely more expensive newer stock last. This ultimately will keep your COGS down and your gross revenue up.

7. Minimise food waste

The relationship between food waste and stock management is a circular one. Reduced food waste leads to better stock control and vice versa.

According to a report by Wrap, food waste costs the UK restaurant sector £682 million a year. We also produce a stunning 915,400 tonnes of it each year.

Such monumental loss is bad for your business, your customers and the environment. So what can you do to reduce food waste in your restaurant?

The easiest and most obvious way to do this is by not overstocking. Use sales reports to determine what dishes sell the most, and which don’t sell as much, then make use of this information when purchasing food inventory for the week.

With the right tools, you can make better decisions about what to buy, in what quantity and when. These considerations should go into creating and pricing menus.

Correct food labelling

One way to reduce food waste and practise better food inventory management is to get your staff into the habit of labelling food correctly.

When decanting food into different containers, make sure you label the date it was made, a sell-by date, as well as any allergens the food may contain. This will greatly improve food safety and hygiene.

Not only will this stop food from spoiling, but it will also avoid potentially dangerous situations where food is unknowingly served to customers with an allergy to its ingredients.

Portion control

Practising portion control is also a sound strategy for improving stock management, reducing food waste, keeping food costs down and even increasing profits.

Using standardised menus for dishes that can be cooked in bulk takes a lot of the guesswork out of portioning.

By using the same recipe each time, you can get an idea of exactly how much of each ingredient you need for a particular dish, as well as how many people it will need to feed in order to turn a profit

Keeping up a system of portion control will help you maximise the value of your stock. Plus, customers appreciate and sense of continuity in their dishes, so good portion control can actually make customers happier and drive higher retention and repeat business.

Find solutions

We’re lucky enough to live in a time where companies and entrepreneurs are using technology to find solutions to societal problems, such as food waste.

Unilever’s Wise Up On Waste app, for example, gives chefs the tools to practise proper waste management in their kitchens

The innovative app Too Good To Go provides restaurants with a simple solution to reduce food waste: offer leftover stock to the hungry public at a reduced price.

Get on top of stock control

If you hadn’t noticed by now, stock control is an indispensable and unavoidable facet of restaurant business management.

Stock management goes beyond your restaurant profit margins. It can affect your workflow, your customers, food supply and the environment.

Equipped with the right tools and processes, along with a team that takes reducing food waste as seriously as you do, it’s possible to cut down on food waste, minimise your cost of goods sold and maximise your stock’s return on investment. Want to know how Lightspeed can help? Let’s talk!

News you care about. Tips you can use.

Everything your business needs to grow, delivered straight to your inbox.